Good User Reputation for Purity Graphite - Application Of Graphite Mould – Furuite Detail:

Product Properties

Product Usage

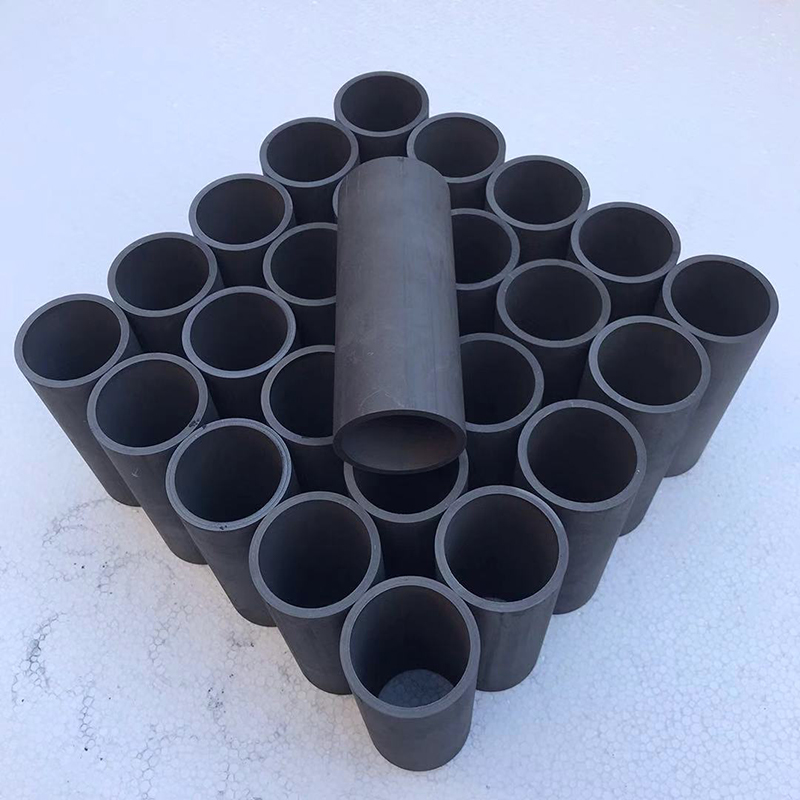

Moulds for glass forming

Because stone graphite material with chemical stability, susceptible to infiltration of molten glass, will not change the composition of the glass, graphite material thermal shock performance is good, the characteristics of small size change with temperature, so in recent years become indispensable in the glass manufacturing mold material, it can be used to manufacture glass tube, pipe, funnel and other forms of special shape of glass bottle mould.

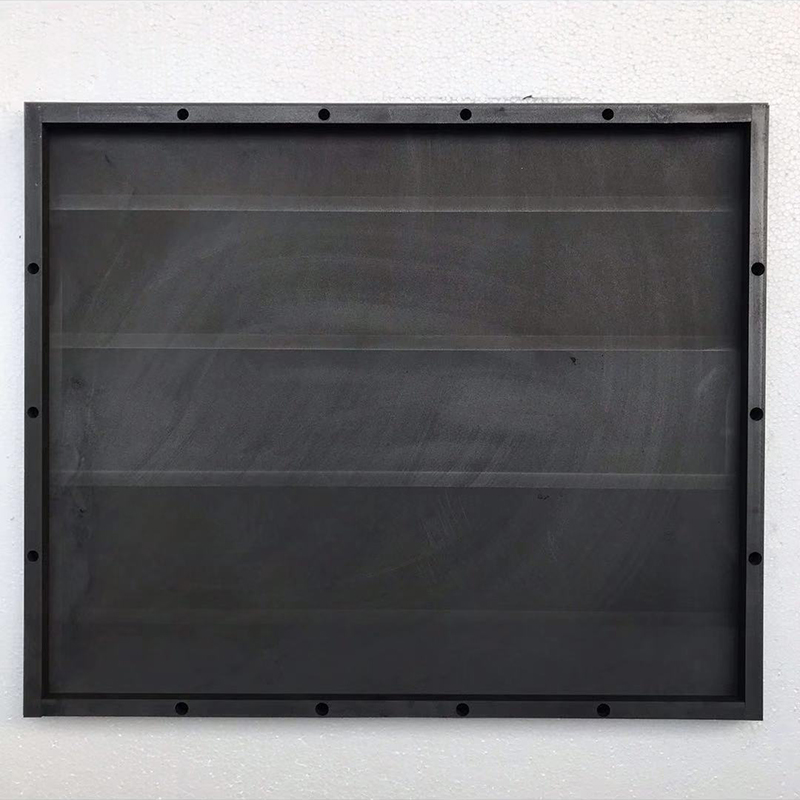

Production Process

Graphite raw material is cut to get graphite mold blank; Grinding steps, grinding the outer surface of the graphite mold blank, get the blank fine grinding pieces; Clamping leveling step, the blank fine grinding parts are installed on the fixture, and the blank fine grinding parts on the fixture leveling; Milling steps, a CNC milling machine is used to milling the blank fine grinding parts clamped on the fixture, and the semi-finished graphite mold is obtained; Polishing steps, the semi-finished product of the graphite mold is polished to obtain the graphite mold.

Product Video

Packaging & Delivery

Lead Time:

| Quantity(Kilograms) | 1 - 10000 | >10000 |

| Est. Time(days) | 15 | To be negotiated |

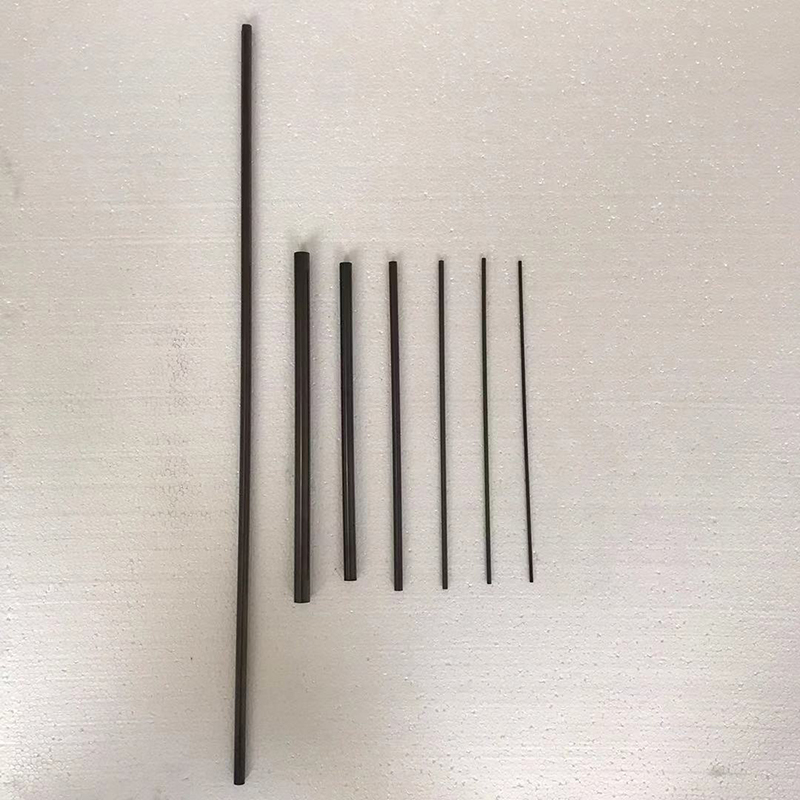

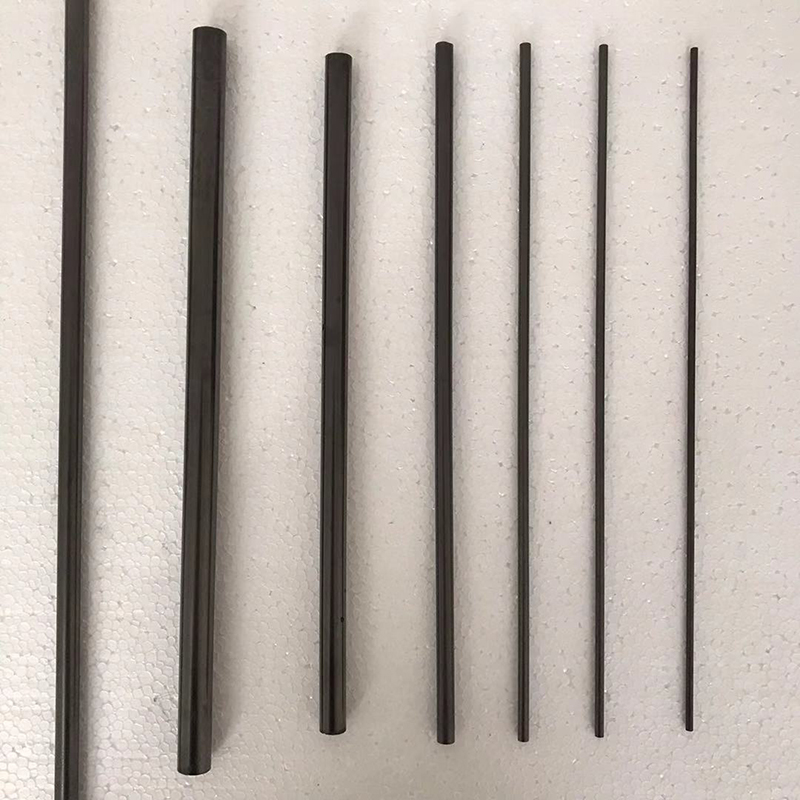

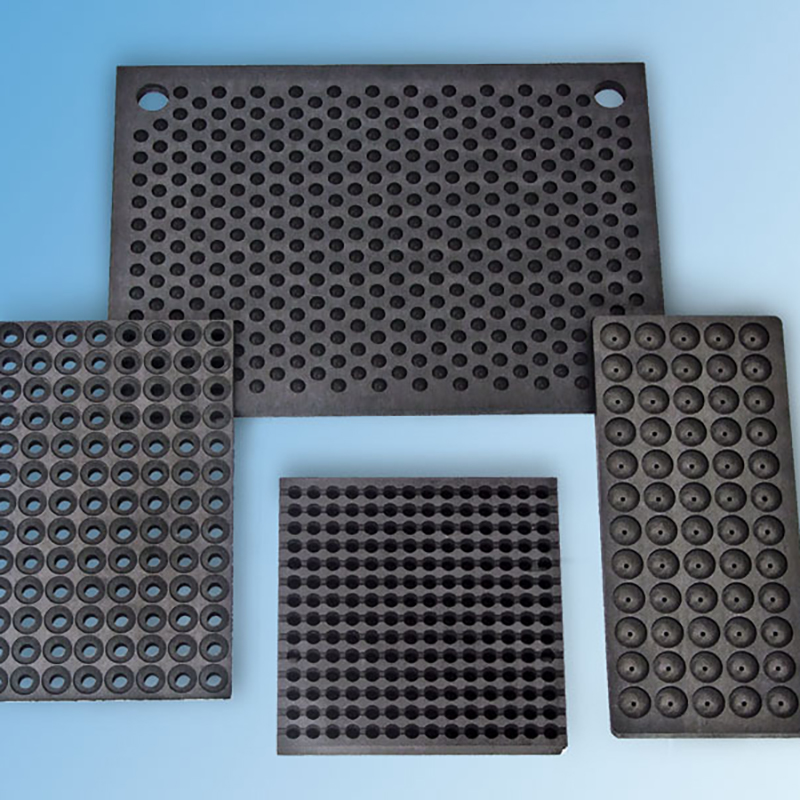

Product detail pictures:

Related Product Guide:

We're committed to furnishing easy,time-saving and money-saving one-stop purchasing support of consumer for Good User Reputation for Purity Graphite - Application Of Graphite Mould – Furuite, The product will supply to all over the world, such as: Puerto Rico, The Swiss, Iran, We hope we can establish long-term cooperation with all of the customers. And hope we can improve competitiveness and achieve the win-win situation together with the customers. We sincerely welcome the customers from all over the world to contact us for anything you need!

The factory has advanced equipment, experienced staffs and good management level, so product quality had assurance, this cooperation is very relaxed and happy!

-

Best quality Flake Graphit Powder - Earthy Gra...

-

Good Quality Graphite Paper Near Me - Flexible...

-

Low MOQ for Uses For Graphene Oxide - Applicat...

-

Reasonable price Pyrolytic Graphite Plate - Ap...

-

Reasonable price for Graphite Flexible Sheet -...

-

OEM Factory for Graphite Sheet Thermal Conducti...