Expandable graphite use scenarios

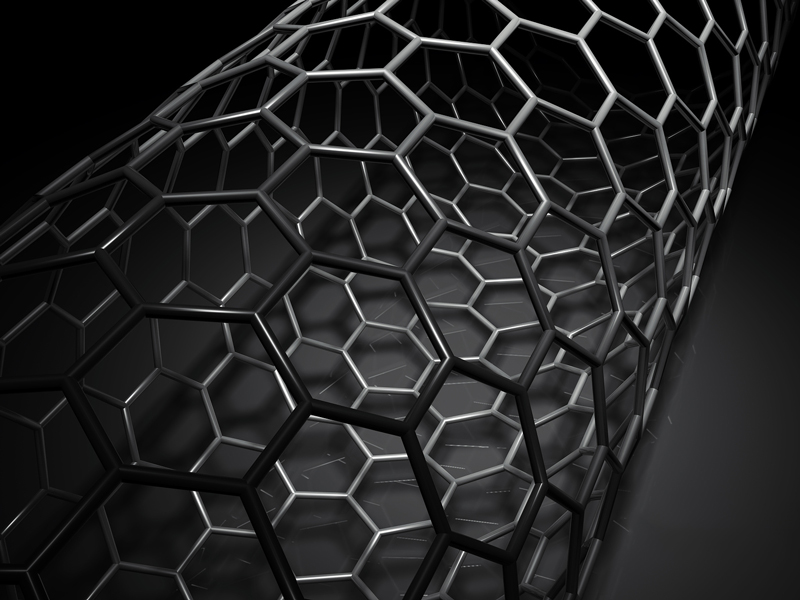

1. The sealing material is mixed with high carbon graphite and concentrated sulfuric acid and nitric acid for acidification treatment, heat treatment and then pressed and formed. The flexible graphite prepared is a new high-performance sealing material, and it is a kind of nanomaterials grown in situ.Compared with asbestos rubber and other traditional sealing materials, it has good compressibility, resilience, self-bonding, low density and other excellent properties, and can be used in high temperature, high decay and other harsh working conditions for a long time.The graphite plates and sealing components made by it are widely used in aerospace, machinery, electronics, nuclear energy, petrochemical, electric power, shipbuilding, smelting and other industries.Because it has light weight, conductive, thermal conductivity, high temperature resistance, acid and alkali corrosion resistance, good resilience, lubrication, plasticity and chemical stability and other excellent properties, known as the world's "king of sealing".

2. The expandable graphite obtained by high temperature expansion in the field of environmental protection has a rich pore structure and excellent adsorption performance, so it has a wide range of uses in environmental protection and biomedicine.The pore structure of expandable graphite is divided into two kinds: open pore and closed pore. The pore volume of expandable graphite is about 98%, and it is mainly large pore with pore size distribution range of 1 ~ 10. 3 nm.Because it is a macroporous, mesoporous mainly, so and activated carbon and other microporous materials in the adsorption characteristics are different.It is suitable for liquid phase adsorption, but not for gas phase adsorption.It is oleophilic and hydrophobic in liquid phase adsorption.1 g expatable graphite can adsorb more than 80 g heavy oil, so it is a promising environmental protection material for cleaning oil pollution on water surface.In the wastewater treatment of chemical enterprises, microorganisms (bacteria) are often used. Expandable graphite is a good microbial carrier, especially in the water treatment of oil organic macromolecule pollution. Because of its good chemical stability and renewable reuse, it has a good application prospect.

3, medicine due to expandable graphite has the adsorption characteristics of organic and biological macromolecules, it has a wide range of application prospects in biomedical materials.

4, high energy battery material expanders graphite as a battery material, is the use of expanders graphite layer reaction of free energy change into electric energy.Usually expandable graphite is used as cathode, lithium as anode, or expandable graphite composite silver oxide as cathode, zinc as anode.Fossil fluoride ink, graphite acid and expandable graphite of metal halides such as AuCl3 and TiF4 have been used in batteries.

5, fire retardant

Due to the expandability of expandable graphite and its high temperature resistance, the expandable graphite becomes an excellent sealing material and is widely used in the fire sealing strip.There are two main forms: the first is the expansion of graphite materials and rubber materials, inorganic flame retardant, accelerator, vulcanization agent, reinforcing agent, filler mixing, vulcanization, molding, made of various specifications of expansion sealing rubber strip, mainly used for fire doors, fire Windows and other occasions.The expansion sealing strip can block the flow of smoke from beginning to end at room temperature and fire.The other is the glass fiber band as the carrier, the expansible graphite with a binder bonded on the carrier, the adhesive formed at high temperature carbonized material provided by the shear force can effectively prevent graphite sliding.It is mainly used for fire doors, but it can not effectively block the flow of cold flue gas at room temperature or low temperature, so it must be used with room temperature sealant.

The flame retardant expandable graphite is a good flame retardant for plastic materials. It has the characteristics of non-toxic and pollution-free. It can achieve the ideal flame retardant effect when used alone or mixed with other flame retardants.Expansable graphite can achieve the same flame retardant effect, the amount is much less than ordinary flame retardant.Its principle of action is: at high temperature, the expansion of graphite can expand rapidly, suffocating the flame, and the graphite expansion material generated by it is covered on the surface of the substrate, isolated from the thermal radiation and oxygen contact;The acid radicals in the interlayer are released during expansion, which also promotes the carbonization of the substrate, so as to achieve good results through a variety of flame retardant methods.

Fireproof bag, plastic type fireproof block material, fire resistance ring because the expandable graphite in high temperature has the ability to resist damage and has a high expansion rate, can be used as fireproof bag, plastic type fireproof block material, fire resistance ring components in the effective expansion flame retardant material, used for building fire sealing (such as: sealing construction pipe, cable, wire, gas, gas pipe, air pipe through the hole and other occasions).

Application in coatings Fine particles of expandable graphite can be added to ordinary coatings to produce better flame retardant and anti-static coatings, and improve their high temperature resistance and fire resistance.The large amount of light non-combustible carbon layer formed in the fire can effectively block the heat radiation to the substrate and effectively protect the substrate.In addition, because graphite is a good electric conductor, the coating can prevent electrostatic charge accumulation, used for petroleum storage tanks, to achieve the dual effect of fire prevention and static electricity.

Fire prevention board, fire paper corrosion resistant and high temperature resistant plate: in the metal base lined with expatable graphite layer, expatable graphite layer and metal base between the carbonized adhesive layer, expatable graphite layer is covered with carbonized protective layer.Corrosion resistance, high temperature and high pressure resistance.At the same time, it can also be used normally at low temperature. It is not afraid of fast cooling and fast heating, and has excellent heat conduction coefficient. The operating temperature is -100 ~ 2 000 ℃.Wide range of application, easy to manufacture, low cost.In addition, the expandable graphite expanded at high temperature, pressed graphite paper, is also used in fire insulation places.